For the blade tip (also known as the electrode or blade tip) of a surgical electric knife pen, 303 stainless steel is a more suitable and common choice than 304 stainless steel. The reason does not lie in which steel is harder or more corrosion-resistant, but in the comprehensive consideration of its mechanical processing performance, electrical conductivity and cost.

| Character | 303 | 304 | The importance of the tip |

Machinability |

Excellent (easy to cut ) | Poor (prone to sticking to the tool and work hardening. | The shape of the cutting head is complex and requires high-precision and high-efficiency production |

| Electrical conductivity | Good (similar to 304 | Good | It is the carrier for conducting high-frequency current |

Corrosion resistance |

Good (meets the requirements | Excellent |

It needs to withstand disinfection and the human body environment, but 303 is sufficient |

| Cost | High processing efficiency and low scrap rate | Hard ,the processing is difficult and the tools wear out quickly | The blade tip is a high-value consumable and its cost needs to be controlled |

Why is 303 a better choice?

The working environment and functional requirements of the surgical electric knife pen tip are completely different from those of ordinary cutting tools. Its core demand is:

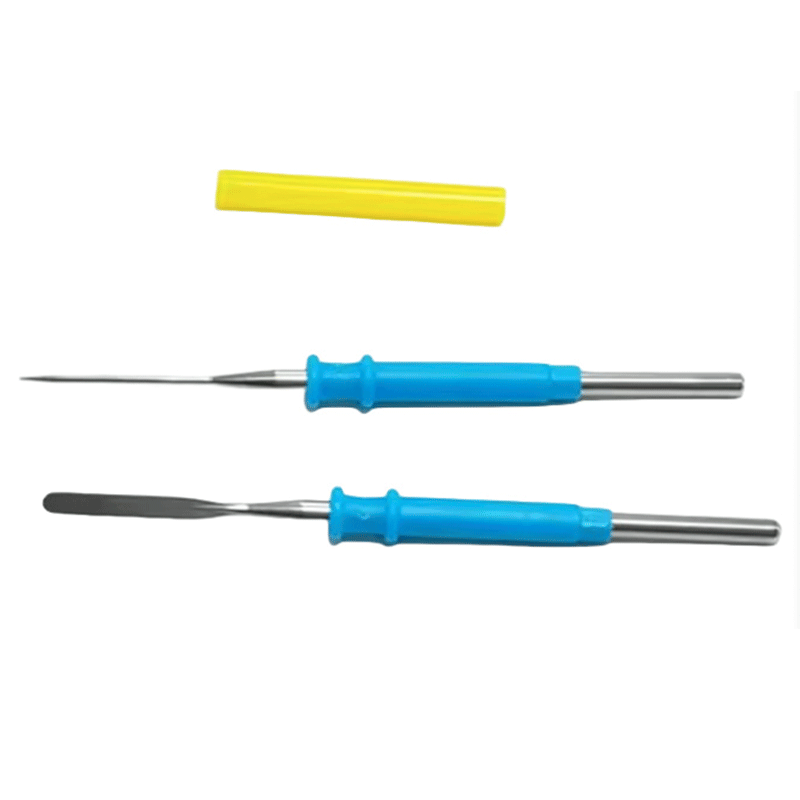

Complex and precise geometric shapes: The tip of an electric knife pen comes in a variety of very fine shapes, such as needle-shaped, spherical, blade-shaped, and ring-shaped. These shapes need to be mass-produced through machining methods such as turning and milling.

Excellent electrical conductivity: The blade head serves as the ultimate carrier of high-frequency current, through which the current is concentrated onto the tissue to generate a thermal effect for cutting or blood coagulation. Therefore, the material must have good electrical conductivity.

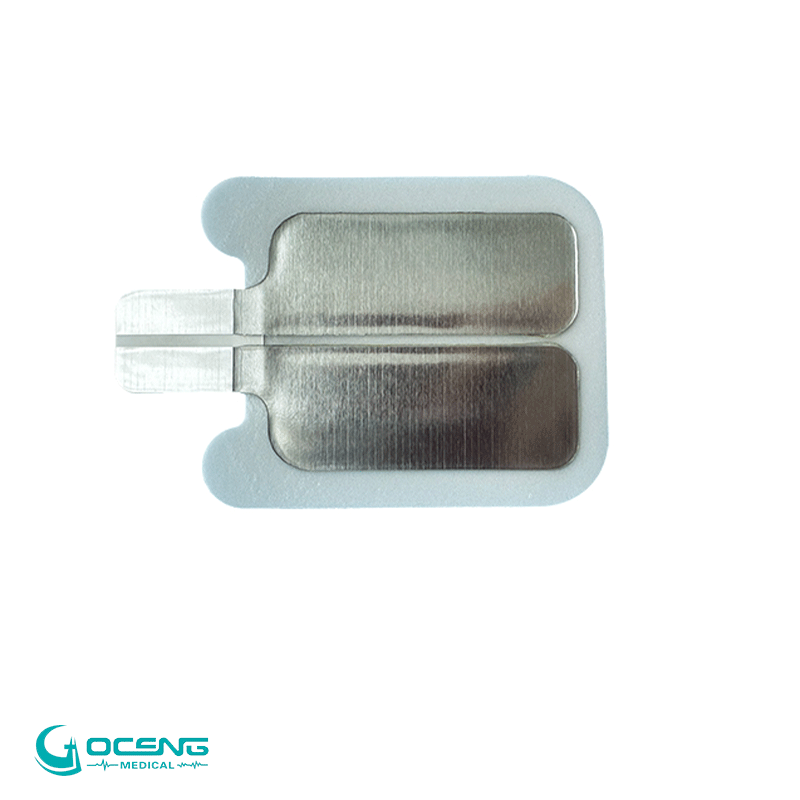

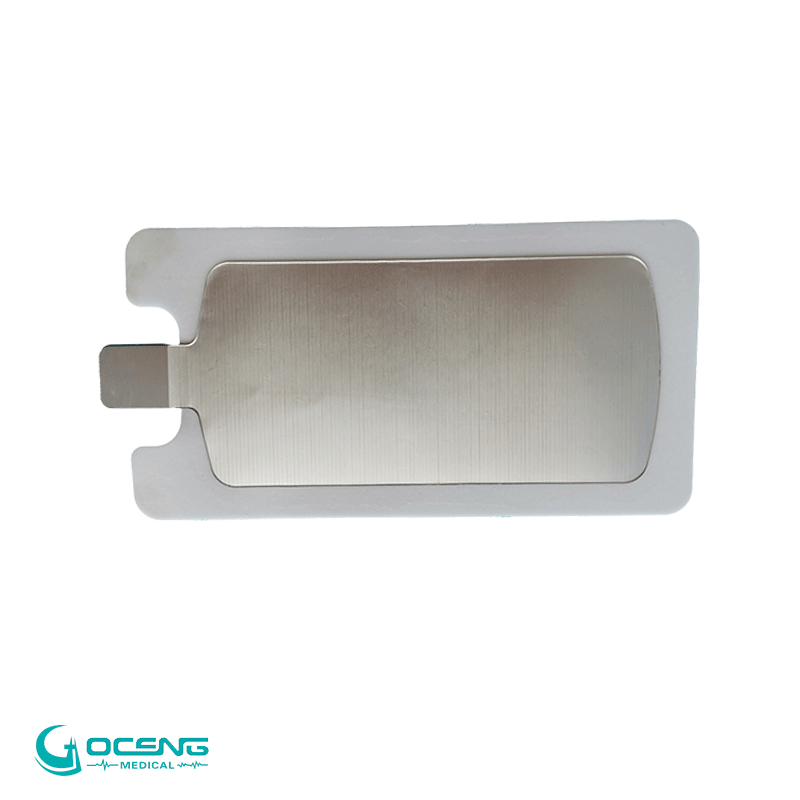

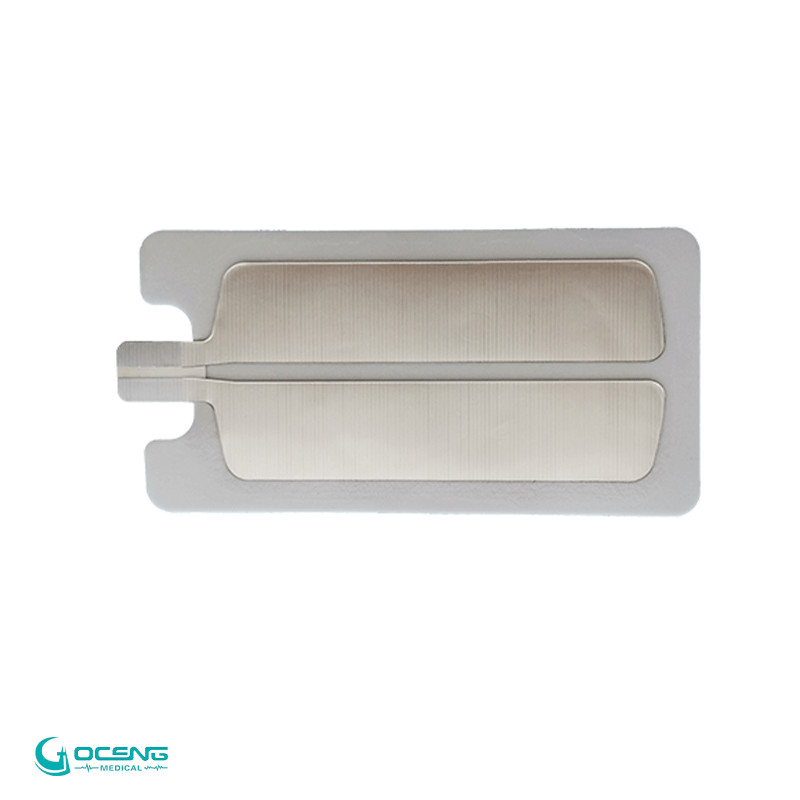

Sufficient corrosion resistance: It needs to be able to withstand repeated high-temperature and high-pressure steam sterilization (disinfection), ethylene oxide sterilization, and contact with human tissue fluid.

Why does 303 perfectly match these demands?

1. Core advantage: Unparalleled machinability

303 stainless steel is a "free-cutting steel" specifically designed for the mass production of parts on automatic lathes such as CNC numerical control lathes. It adds sulfur or selenium, which makes chip removal easy during cutting, results in a good surface finish, and can significantly increase the processing speed and reduce tool wear.

For electric knife pen manufacturers: This means they can produce complex-shaped knife heads with higher precision and efficiency in a shorter time and at a lower cost, and the yield rate is very high. This is a decisive factor for a disposable high-value consumable that requires large-scale production.

2. The fatal drawback of 304: Poor machinability

304 stainless steel has obvious "stickiness" and "toughness" during processing, which can easily produce long and hard-to-break chips that wrap around the cutting tool and workpiece, affecting the continuity and safety of automatic processing.

More importantly, 304 has a serious tendency towards work hardening. During the cutting process, the machined area will become extremely hard due to plastic deformation, making subsequent processing difficult, dimensional control hard, and severely wearing the processing tool.

For electric knife pen manufacturers: Using 304 to produce complex knife heads will lead to low production efficiency, high tool costs, poor product size consistency and high scrap rates. This is commercially unacceptable.

Comparison of other features

Electrical conductivity: Both 303 and 304 are austenitic stainless steels, and their electrical conductivity is relatively average (far inferior to that of copper or aluminum). However, as high-frequency current conduction media for electric knife pens, the difference in electrical conductivity between the two is very small, and both can meet the usage requirements. The "skin effect" of electric current causes the current to mainly be distributed on the surface of the conductor, and the conductivity of stainless steel is not a bottleneck.

Corrosion resistance

The corrosion resistance of 304 is indeed superior to that of 303, as the sulfides in 303 May serve as potential starting points for corrosion.

However, for the tip of an electric knife pen, the corrosion resistance of 303 is already sufficient. It is fully capable of withstanding standard medical disinfection procedures and brief contact with human tissues. The blade head is for single use or a limited number of uses and does not need to remain stable in the body for a long time like implants. Therefore, sacrificing processability and cost for a little extra and unnecessary corrosion resistance is not worth it.

Hardness and strength: Both belong to low-carbon austenitic stainless steel and cannot be strengthened by heat treatment. Their initial hardness and strength are similar. For electric knife pens, their cutting effect mainly relies on the thermal effect of the current (high-temperature vaporization of the structure) rather than mechanical pressure. Therefore, the hardness requirement for the material of the cutting head itself is not high. As long as it is not prone to bending or deformation during operation, both 303 and 304 can meet the requirements.

Choosing 303 stainless steel as the material for the blade of a surgical electric knife pen is the best solution after balancing performance, manufacturability and cost in engineering. In this specific application of surgical electric knife pens, 303 is the correct choice that is significantly superior to 304.